● V-cutting blades system

● Way-back

● High Stability

● Versatility

● Two single wires can be processed at the same time with double blades and guides

● Extra long stripping and multi-stage stripping

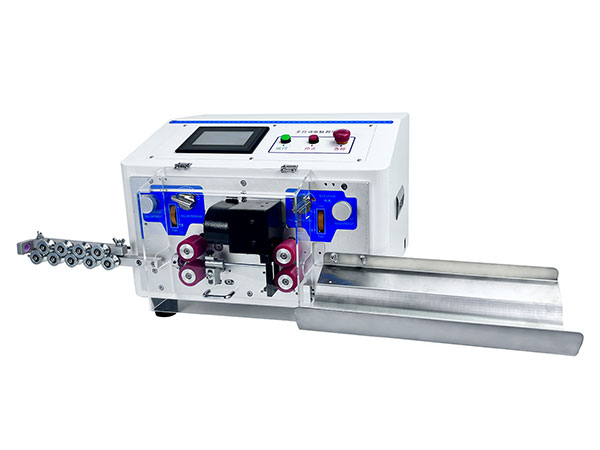

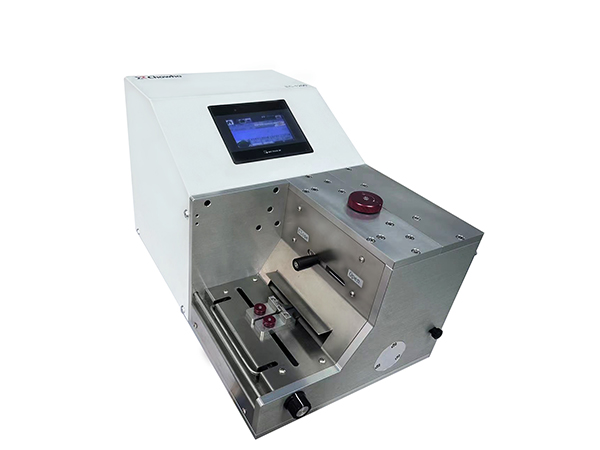

Automatic cut&strip machine AS-810 can be used for processing all kinds of circular cables,the maximum outer diameter of wires can be up to 7mm. This sturdy machine can process all kinds of thick,hard,soft and thin wires and cables,and adopts the latest 32 bit intelligent control system,The LED screen have operation interface of Chinese & English, and can be exchanged by itself, the simple of operation, efficient and convenient.The all parameters can be set arbitrarily within the machine processing capacity range. It's suitable for normal wires and cables to cut and strip, such as electronic wire,multi-core cables,etc.

● Process all kinds of thick and hard insulating materials wires.

● Window stripping and stripping with partial.

● 4.3 inch touch display.

● Wire transfer more accurate adopt four rollers drive mode.

● No need to change blades.

● High flexibility.

| Display Mode |

4.3 inch touch display |

| Cable Outer Diameter |

Min. 0.3mm(inner);Max.7mm(Jacket) |

| Diameter Increments |

±0.01mm(depend on the cable outer diameter) |

| Length Increments |

+/-0.1mm |

| Stripping Length |

Left side: 0.1~50mm,Right side:0.1~30mm |

| Cutting Length |

0.1-99999.9mm |

| Tangent tolerance |

Within 0.002*Lmm |

| Drive roller Pressure |

Adjust |

| Production Rate |

3000~5000Pcs./hour(depend on the parameters of processing) |

| Max.multistep Stripping |

13 times |

| Way-back Increments |

+/-0.01mm |

| Blade |

V-blades(HSS&Carbraide |

| Cables Meterial |

BV,BVR,PU,PVC,PUR,rubber,Teflon® ,Tefzel®,Kapton,etc. |

| Display Interface |

Chinese/English |

| Program Capacity |

100 cables with 13 steps |

| Options |

Cable guides(1.5~7mm) |

| Air Supply |

0.5-0.7Mpa(5-7bar) |

| Power Supply |

AC220~240V ,50~60Hz,Fuses 3.15A,180VA |

| Noise |

< 70 dBA |

| Dimensions (L x W x H) |

420x297x345 mm |

| Weight |

28Kg |

| Important Notice |

Chowho company recommends that wire samples be submitted in case where there is doubt as to the processing capabilities of a particular machine. |

|